2021-01-11

Safe connections for dynamic forces

RINGSPANN supplies machine tool manufacturers with powerful drive components

As a premium manufacturer of components for industrial drive technology, RINGSPANN also has a wide range of innovative design elements to offer the international machine tool industry. For example, the company supplies well-known manufacturers in the industry with high-quality shaft-hub-connections and overload couplings as well as clamping systems for the installation of high-torque torque motors and compact electric brakes. Find out which components from the company’s portfolio are now becoming standard equipment for many machine tool manufacturers.

Bad Homburg, January 2021. – When it comes to looking for components for the drive systems of your machines and machining centres, RINGSPANN’s one-stop shop has established itself as one of the go-to supply sources for a number of large machine tool manufacturers. "It is primarily manufacturers of machines and systems for metal cutting and metal removal who have us supply them with shaft-hub-connections, overload couplings, torque motor clamping systems and brakes to optimise the performance and operational safety of their machine tool drives", reports product manager Marvin Raquet.

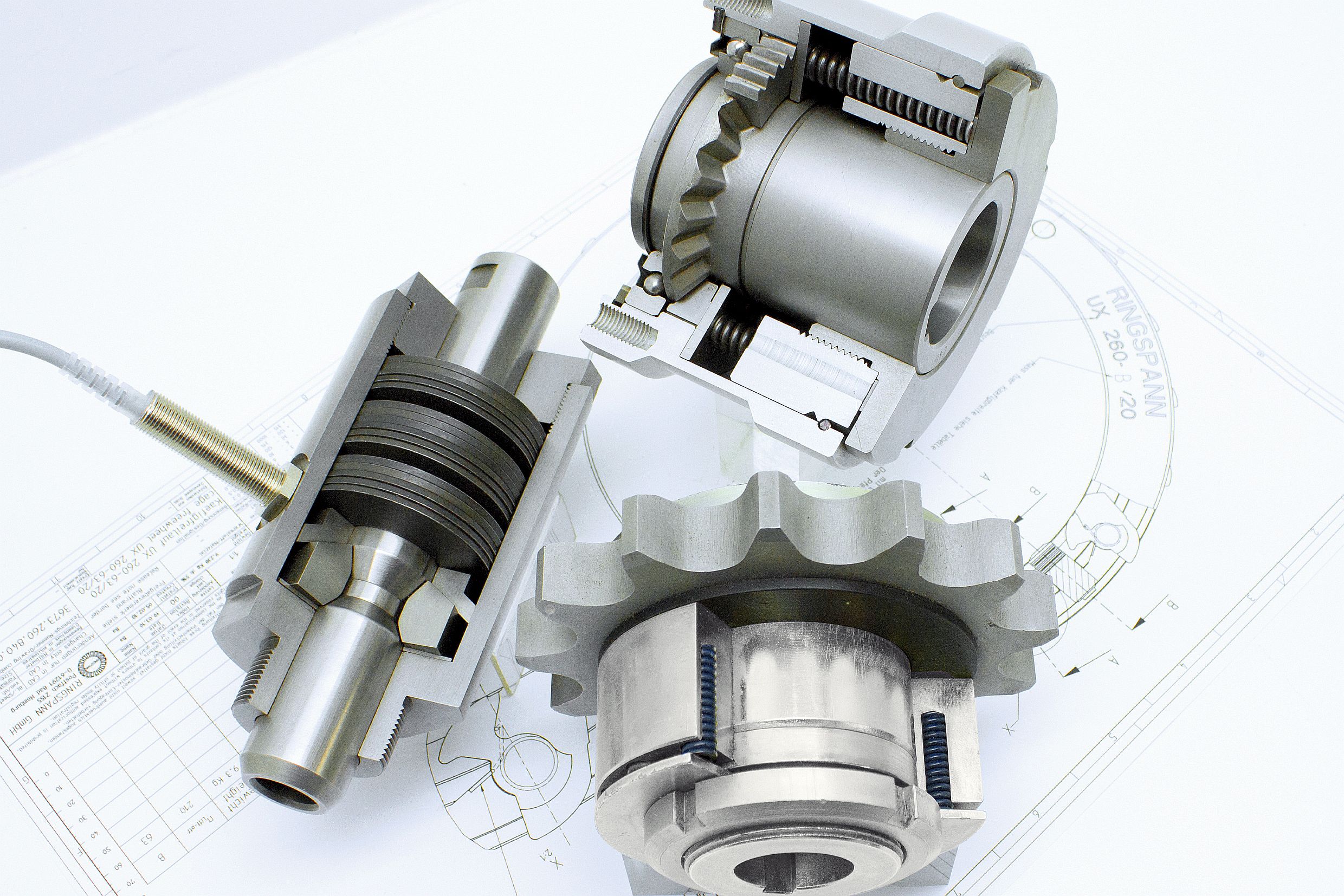

In the area of shaft-hub-connections, for which Marvin Raquet is responsible, it is above all the conical clamping elements in the RINGSPANN portfolio that are always the focus of machine tool manufacturers. These internal clamping connections, which operate according to the frictional locking principle for play-free fixing and centring of hubs on shafts are available to machine tool designers in many types and variants. The clamping elements of the RLK 200 and RLK 350 series, for example, have established themselves as a cost-effective standard solution for use in belt drives. They differ in significant aspects and already reveal the broad range covered by RINGSPANN’s shaft-hub-connections range alone. While the RLK 200 series is designed for shaft diameters from 20 to 400 mm and transmittable torques from 300 to 428,500 Nm, the elements of the RLK 350 series are suitable for shafts with particularly small diameters from 5.0 to 50 mm and torques from 7.2 to 2,200 Nm. Other shaft-hub-connection series, on the other hand, are characterised by their extremely compact design without clamping screws (RLK 300), offer heightened corrosion protection (RLK 110 K), are suitable for very thin hubs (RLK 110) or transmit exceptionally high torques up into the seven-digit range (RLK 404).

Mounting direct drives safely

The RTM 60... and RTM 134... series form a special group within RINGSPANN’s shaft-hub-connections portfolio. They are clamping systems for the installation of torque motors in machine tools that are adapted to various installation scenarios. They are principally suited for frictionally locking and centring the built-in and complete torque motors of well-known manufacturers on shafts or hollow shafts, whereby their design is oriented both to the special requirements of these direct drives and to the machine shafts used for them, which are often designed as thin-walled hollow shafts. "The stand-out features of our clamping systems for these permanent magnet-energised synchronous servo drives include above all the safe, play-free transmission of the torques and a very high centring and concentricity accuracy", emphasises RINGSPANN manager Marvin Raquet.

Setting limits up to 140,000 Nm

In addition to shaft-hub connections and torque motor clamping systems, machine tool manufacturers will find another drive-related product group in the RINGSPANN portfolio that is virtually indispensable for the reliable operation of the main and auxiliary drives of highly dynamic machine tools and machining centres: ready-to-install overload clutches in numerous sizes and variants. Especially with the positive ratcheting, synchronous, separating and locking torque limiters in the SIKUMAT® family as well as the frictionally engaged RIMOSTAT® torque limiters, the company offers an extremely attractive selection of powerful overload protection devices for machine tool drives and spindles. Across all series, they are suitable for use at speeds ranging from 1,000 - 13,000 min-1 and cover limit torques from 0.5 to 60,000 Nm. "Our bi-directional force limiters, which can absorb disengaging forces of 3,600 to 140,000 Nm, are also specially designed for the overload protection of push and pull rods," adds Marvin Raquet.

Fast procurement thanks to the one-stop shop

Since the entire RINGSPANN one-stop shop is geared towards the concept of cross-selling, designers and buyers in the machine tool industry can procure many drive technology components from a single source. "Wherever shafts and axles of highly dynamic machine tool drives need to be securely mounted, braked in a controlled manner, reliably protected against overload, while at the same time reducing costs for assembly, our one-stop shop can serve as a central procurement and information platform for customers," says RINGSPANN manager Marvin Raquet. ar

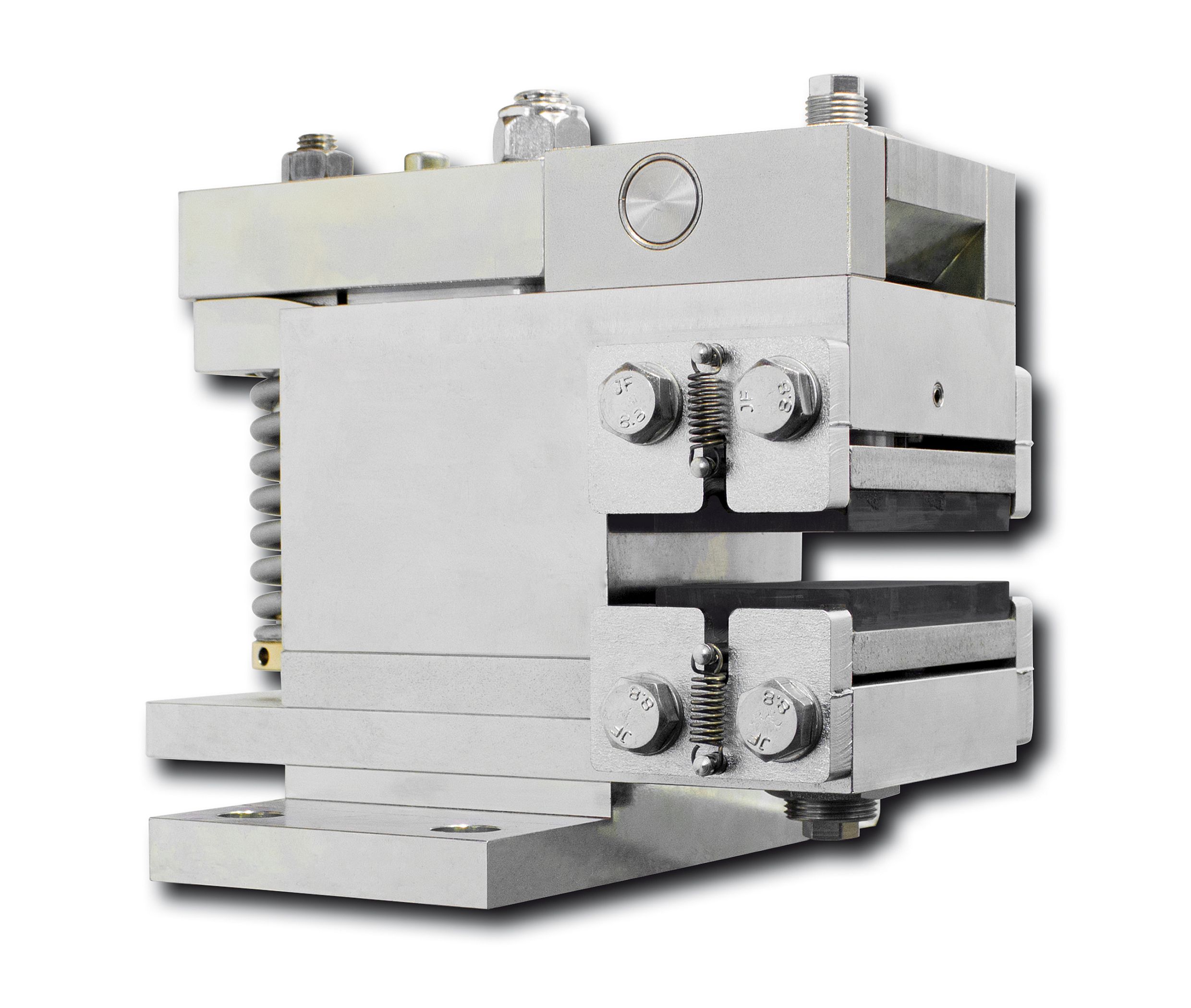

Brakes for all machine tool axes

In its role as a one-stop supplier of drive technology components, RINGSPANN also offers a wide range of brakes. Compact electromagnetic disc brakes are particularly relevant for the machine tool industry. They can be used for the braking, holding and emergency stopping of gravity-loaded and driven axes as well as linear axes and rail guides. The electronically controllable disc brakes in the EV and EH series, for example, convince thanks to lean installation dimensions, low weight (from 6.5 kg), Industry 4.0 features (e.g. sensory monitoring) and energy efficiency. In the holding phase, they have an extremely low power consumption - the smallest models only require 10 watts. In the field of e-brakes, RINGSPANN currently offers 16 basic types in four frame sizes with clamping forces from 1,800 to 24,000 N. Across all technologies, the company’s industrial brake portfolio encompasses around 60 series with braking torques from 0.5 to 600,000 Nm.